Recent developments in packaging, major changes in packaging quality and visual quality provided benefits in an excellent image and reduce the cost of packaging. Qualified and professional packaging is an important point that boosts both of the product and manufacturer’s reputation. In addition to the developments in this area, similar packaging techniques and machines have been developed to ensure the batch delivery of the products and let them reach the maximum number of products without any damage. The application called shrink is one of them.

Shrink Packaging

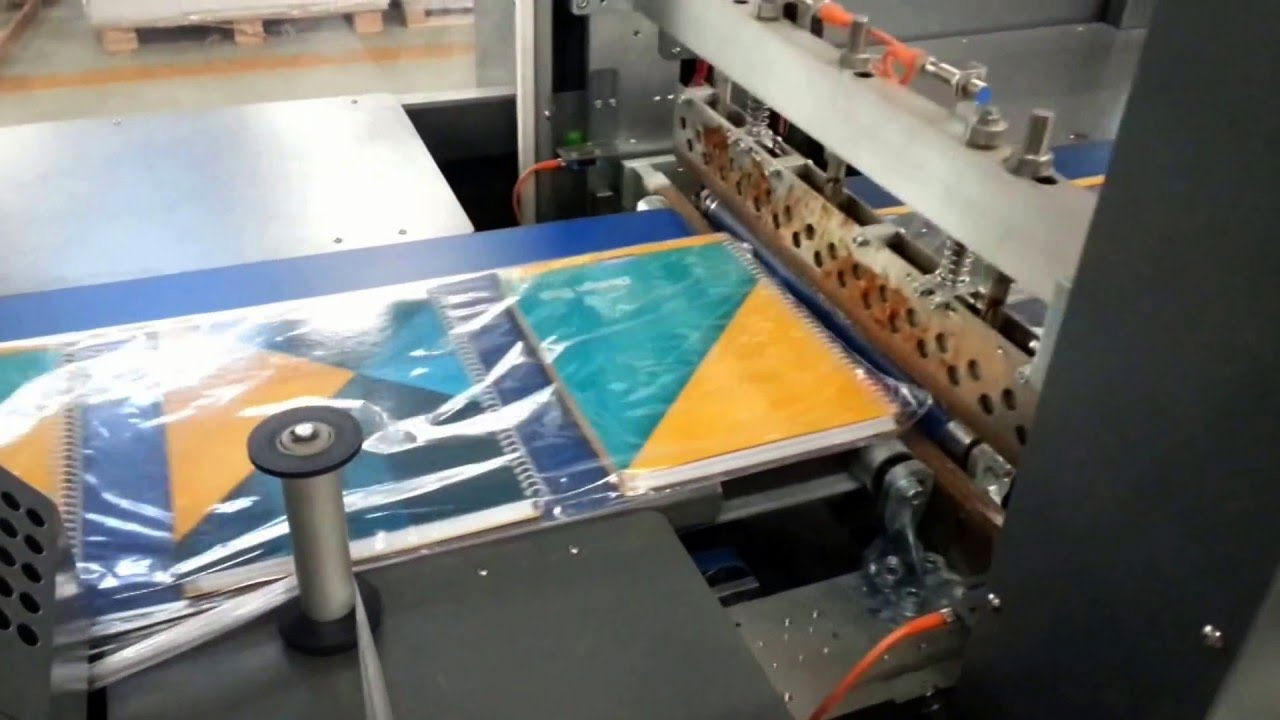

Basically, shrink is defined as a film application on the packaged products or products that will be packaged. The film-making material used in this technique enters the form of the material to be packed by heat. In this way, excellent packaging stability and protection of the previous packaging will be protected. Designed and used machines to do this are called shrink machines. Wrapping the film-making material on the packaged product is the first stage while ensuring that this material takes the form of the material that it is wrapped with heat is the second stage. Many examples can be given for the question of where are the shrink machines that carry out this operation. However, we can say that it can be used in every field that requires larger volume packing for the multiple packaged or unpackaged material as the basic requirement. Although shrink machine design change according to the intensity or qualities of the areas of use, it is defined as the goal of providing shaping with heat by covering with the film-making material.

Shrink Usage Areas

Shrink machine designs can be designed for many different uses or purposes. In general, these machines are designed to provide a stand-alone form for the unpackaged products or assemble the packaged products as a single package. They can be used in many areas from food to chemical industry.

As the most common goal about where a shrinking shrink machine is used can be defined as protecting a product or a collection of packaged products from fixed, external factors and keeping its own form. One of the areas of use that is shaped around this is the storage issue. One of the protection measures taken during storage is the shrink packaging. In this way even all kinds of measures are taken on this, the material will be ensured to be protected from the negative physical conditions of storage and dangerous living beings such as insects. Another purpose of the use is the delivery of the products specially made from delicate materials will be carried out to the delivery point or buyer without any damage during any kind of transportation, shipping etc.

It is possible to give many examples such as this for this system that provide compact and reasonably suitable packaging for all kinds of production storage about where a shrinking shrink machine is used. This type of packaging which is carried out both for protection and security purposes is a very common type of packaging in recent times. This is why significant progress has been made in terms of both the trade of used materials and on the design of the machine.

Shrink Machines

There are many different models or manufacturers of machines. Apart from this, depending on the method and packaging used main machine designs can be found as L Joining and Continuous Cutting. Capacity, work to be carried out and outcomes must be analyzed very well before you make a choice for a machine. Machine manufacturer must consider issues such as material and service continuity when selecting machines. Again with the heat field and qualities during the operation with the operator’s ability to use the machine must be taken into consideration. All of these criteria are important.