How to Choose the Right Shrink Film for the Right Shrink Packaging Machine

Packaging with Shrink Film usually applied to the desired product or item with heat emission. Packing process may have been carried out with various standards.

Maripak USA Has Opened Its Doors Since 1st Of July

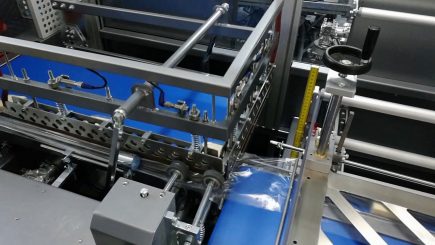

Our New Semi-automatic Shrink Machine: TMC Pro

In new TMC not only the color but many other essential parts have changed. First of all, we have put the electric panel cabinet inside the machine which was previously positioned outside.

Control Points of Quality Shrink Packaging

Information About Packaging Machines

The Importance of Perforation in Shrink Packaging

Shrink Packaging

Why Shrink Packaging and Other Questions to Ask

Many special design Shrink films have been produced for different types of different applications. As far as costs are concerned in choosing the right film, it should be carried out by considering the requirements of the packaging system.