Shrink machines vary according to their usage area. However, the technology led to the shrink machine manufacturers find new inventions and in this sense, the manufacture of shrink machines in our country has come to the top in terms of the exports to abroad.Accordingly, we have industrial establishments that implement technology that will make the old shrink machines up to date. Shrink machine parts are consists of the following headings.

Shrink machine parts are consisting of parts such as;

– Tower front pan

– Tower rear pan

– Aluminum hot jaw

– Machine engine

– Conveyor

– Conveyor engine

– Tunnel

– Tunnel heat circulation engine

– Thermostat

– Cooling fan

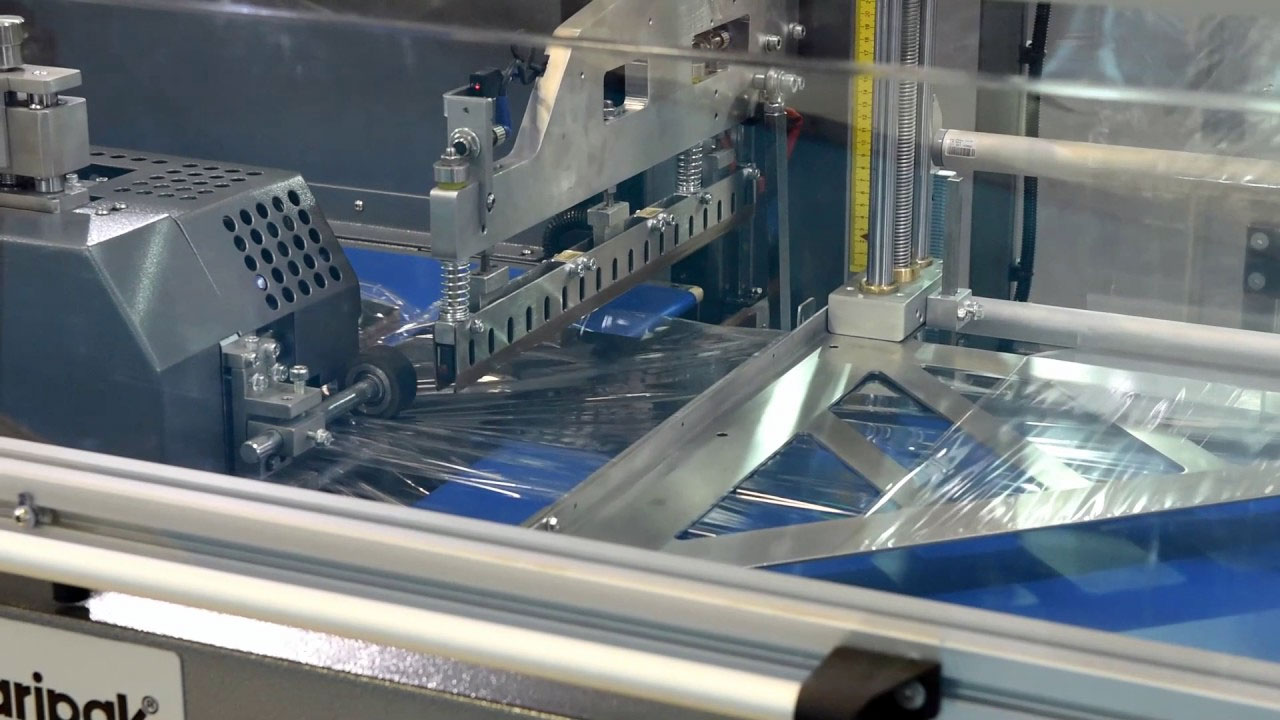

The most important element in today’s technology is the usage of shrink machines that applies how jaw process.

Because of advanced technology in hot shrink machines and the rise of quality, no any failure will be experienced in shrink machines thanks to the technology adopted in the jaw section. The advantage of the hot jaw according to other shrink machines is; wire harness found in old machines used to constantly break and fail, and the replace the broken parts used to take about 60 minutes effort. In this newly developed system both work and time lost eliminated and workflow and production become faster because it is longevity.

It can be done at once thanks to tower front and rear pan, conveyor, the operation engines in the tunnel and hot jaw and it becomes more efficient for mass production.

These basic shrink machine parts are indispensable features of shrink machines. Shrink machines can vary according to the fields and industries that they are being used.

For instance some of the examples of the shrink machines are; printing shrink machines, door furniture packaging shrink machines, cosmetic shrink machines, food shrink packaging machines, box shrink machines, aluminum profile shrink machines, Stratfor shrink packing machines, perfume shrink machine, cabinet shrink machine, spare parts shrink packing machine, parquet shrink packing machine, paint shrink packaging machine, water packaging shrink machine, cable shrink packaging machine, solar panel shrink packaging machine, stationery packaging shrink machine, sorb shrink machine, jar and bottle shrink packing machine. Shrink machines are manufactured according to product varieties for organizations that manufacture in almost all sectors.

Shrink machines are specially produced in 3 kinds as automatic, fully automatic and semi-automatic and according to the characteristics of the sectors and packaging systems.

The control screens are touch screens in fully automatic shrink machines and they weigh 300 kg more than semi-automatic shrink machines with a weight of 750-800 kg.

Other values are close to one another between semi-automatic machines and automatic shrink machines apart from serial production format and electronic touch screen.

Shrink machines and shrink machine parts can also be produced from stainless steel