A Revolution In Sealing Technology

Maripak presents the new sealing system that provides perfect control and better tamper evidence in wrapping with films above 50 micron.

What is New?

In conventional sealing systems, the cutting knife is used both for sealing and cutting. But when the packaging film is thicker than 30-40 microns, (>2 mil) the thickness in the sealing area is too bulky to seal and cut at the same time.

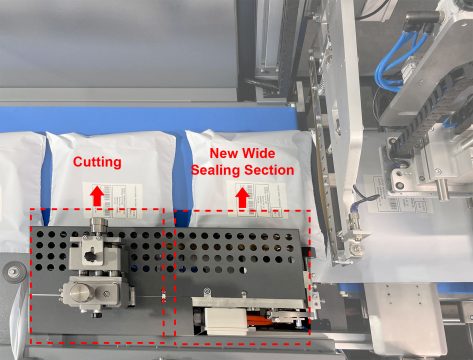

The new system works on the principle of isolating the sealing and cutting processes.

The sealing is carried out under a pressure-controlled heat-proof band-sealing principle. As the sealing is as wide as 10mm, in the neighboring station, the sealing line is split by a cutting knife to leave only the necessary part of the wide seal.

Using the above principle, the knife and sealer block are activated individually while the film is still on hold. As the end result, accuracy in the sealing width and the quality of the sealing pressure is provided with great success.

The Cross Sealing System

The sealing and cutting points are also isolated.

The system is equipped with a special edge design and temperature control. The top and bottom parts are equipped with a temperature-controlled knife and a separate cold knife is located in the sealing area. During the sealing process, the wrinkles on the cross sealing and multiple layers on the sealing point can be sealed and cut with great success.

Who Is It For?

The new sealing technology has been developed especially for food/nonfood and liquid applications which make it a perfect secondary packaging solution for a wide range of industries. It answers the need for resilient, protective, and tamper-proof packaging especially for customers in areas of:

- E-Commerce

- Household Detergents

- Liquid Retail Products

- Heavy Materials